Cost to Install Concrete Pad 2019 Cost Calculator ...

For a basic project in zip code 47474 with 120 square feet, the cost to Install a Concrete Pad starts at per square foot*. Actual costs will depend on job size, conditions, size options.

WhatsApp)

WhatsApp)

For a basic project in zip code 47474 with 120 square feet, the cost to Install a Concrete Pad starts at per square foot*. Actual costs will depend on job size, conditions, size options.

About 50% of these are mine mill, 7% are grinding equipment, and 3% are other fabrication services. A wide variety of ball mill prices options are available to you, such as ac motor, dc motor, and stepper motor. You can also choose from free samples, paid samples. There are 17,194 ball mill prices suppliers, mainly located in Asia.

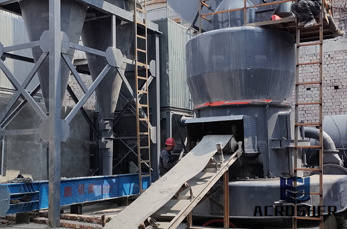

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

cost of cement grinding mill ofspescaracolliit. Cement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement .

Nov 06, 2017· About 10000–30000 Contact Number Telephone: Cellphone: Email:shuguang_ballmill Zhengzhou Shuguang Heavy Machinery Co., Ltd. was founded in 1993, the company headquarters is located in the beautiful city ...

James Hardie x 144in HZ10 HardiePlank Cedarmill Fiber Cement Lap Siding at Lowe''s. As America''s #1 brand of siding, James Hardie® fiber cement siding and trim bring beautiful design and superior performance to homes from coast to

meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding. The mill can be used for pregrinding and finish grinding. This millsystem claims to have advantages of ball mill, roller mill and roller press in terms of reliability and energy savings. The energy saving is claimed to be

Aug 04, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are .

what is the cost of cement mill vertical roller type A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills

Cement mill is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics, etc.. Cement mill can grind ore or other materials by wet process or by dry process.

Dec 01, 2017· Grinding cement requires a great deal of energy. As the fineness of the cement increases, it needs more energy to grind it. But every cement quality band has a certain fineness requirement. In one example mill, we consider the fineness and the energy consumed for eleven months for a cement mill.

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

Cement mill plant cost. In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials including raw materials, fuel, clinker, mixed materials,gypsumGrinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%

Mill Valuation Study Avino Silver Gold Mines Ltd. Mining and Mill Costs have increased by 150% since 2001; capital .... space with reasonable gradients adjacent to the existing tailings to construct a new ... There are sufficient usable buildings at the site for an ongoing 1000 TPD operation.

cost of tph cement grinding vertical mill. 250 tph loesche cement mill Cost of 20 tph cement grinding vertical mill sand washing machine/solutions/solutions html price details for 20 tph ball mill price stone crusher 30 tph price stone crusher 3 50 Tph Vertical Roller Pre Grinding Mill.

cost for cement grinding mill. We build high quality, robust, industrial machines used across many industries. Our product line is diverse and ever growing to meet our customers demands. HOME cost for cement grinding mill. Vertical Roller Mill For Cement GrindingOre Milling Equipment.

South Carolina Concrete Costs Prices We have collected data statewide to help calculate the average cost of concrete in South Carolina. The following are average costs and prices reported back to us: Cost of Concrete Foundation Installation in South Carolina.

Concrete mill stands replace the traditional steel structures, reducing installation time and costs. Using concrete also means lower mill vibration at the foundation. The highperforming vertical roller mill generates minimal noise during operation due to the lower level of mill vibration. This makes installation without a building feasible.

Aug 30, 2012· This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

patent and started selling an improved version of this mill all over the world. For the cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

Pavement milling (cold planing, asphalt milling, or profiling) is the process of removing at least part of the surface of a paved area such as a road, bridge, or parking lot. Milling removes anywhere from just enough thickness to level and smooth the surface to a full depth removal.

A cement mill is key equipment for recrushing the materials after they are primarily crushed. It is widely used in the dry type and wet type powder grinding of all kinds of ores and other grindable materials in cement, silicate product, new type building material, refractory, fertilizer, ferrous metal, and nonferrous metal beneficiation and glass and ceramic production industry.

WhatsApp)

WhatsApp)