Hydraulic circuit for milling machine_Nirma University ...

Oct 31, 2015· This video lecture is prepared by 5th semester students as a part of term assignment in subject hydraulics and pneumatics.

WhatsApp)

WhatsApp)

Oct 31, 2015· This video lecture is prepared by 5th semester students as a part of term assignment in subject hydraulics and pneumatics.

A vertical roller mill for carrying out the method according to claim 1 the mill comprising at least one grinding roller (3) which is urged by a double acting hydraulic cylinder (9) against a grinding table (1) rotating about a vertical axis characterised in that both ends of the hydraulic cylinder are connected to an electro hydraulic servo

Mar 25, 2015· Hydraulic system vertical roller mill operation 1. The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts ...

Feb 05, 2013· This video is about Atox Mills Hydraulic Unit for grinding rollers. Process carried out through various control valves mounted on a hydraulic block called Black box or Swiss cheese.

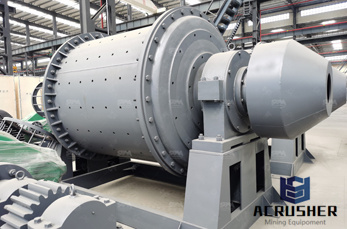

Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

• Closed Loop Hydraulic Systems, • Primary autogenous milling lubrication and Hydraulic systems, • Turbine Lubrication systems, • High end critical rotating hydraulic lubrication circuit equipment. LOCALLY DEVELOPED AND MANUFACTURED ISADRAULICS OFFICIAL NW/QLD SERVICE PARTNER TO HYDAC. LOCALLY SERVICED AND SUPPORTED. LOCALLY .

Discover our advanced CNC machining solutions including MultiTasking, 5axis, milling, turning, CNC controls and automation.

vertical roller mill hydraulic system: component used for applying sufficient pressure to the grinding roller to crush materials. Controlled System Pressure applied to the grinding roller being automatically controlled by the PLC/dCs enables the accurate control of grinding pressure and the highly efficient and stable operation of the mill ...

Hydraulic Vertical Log Stops the same dependable design we''ve used for years, beefed up with solid twobytwo steel uprights. Hydraulic Log Loaders with twin, 5ton rams, 1″ thick steel loading arms, selfattenuating supports, 5,000 lbs. capacity! HighSpeed Hydraulic Log Clamp allows you to remain at control panel. One lever moves powerful ...

Apr 07, 2013· Hydraulic cylinders, for example, are designated by Z or HZ (Z1,Z2, Z3 etc.) or in alphabetical order using A, B, C etc., whilst hydraulic motorscan be designated by HM or additional designation purposes, the hydraulic circuit diagram may alsocontain details of pumps, pressure valves, pressure gauges, cylinders, hydraulic motors, pipes ...

Hydraulic Circuit Diagram For Vertical Roller Mills Hydraulic cone crusher, the latest generation of crusher in today''s mining construction industry, can replace spring cone crusher and general hydraulic cone crusher, and it is ideal equipment in large stone plant and mining crushing.

Hydraulic Circuit Diagram For Vertical Roller Mills Cone. Hydraulic Pressure And Vertical Roller Mill Caesar Heavy. Grinding pressure in vertical roller mill cement mills and raw mills for high throughput rates therefore ease of replacement and regeneration is a major feature of the millhe mvr mill has a modern hydraulic system used in operation and for maintenance alikeith this new type of ...

If the Hydraulic Roller Press is used for finish grinding in a closed circuit with the twostage separator system, the need for other grinding equipment is eliminated. The reliable Hydraulic Roller Press outperforms ball mills and vertical mills when it comes to finish grinding.

The hydraulic circuit for a milling machine is comparatively different from the hydraulic circuit of the surface grinding machine and hydraulic circuit of the shaper machine. This is because the table movement in milling operation is comparatively slower.

Oct 25, 2014· Figure shows a circuit in which speed control in a hydraulic circuit is accomplished using a pressurecompensated flow control valve. The operation of the circuit is as follows: • In the springcentered position of the tandem fourway valve, the motor is hydraulically locked.

hydraulic layout circuit for grinding machine. ... hydraulic circuit diagram for vertical roller mills, ... hydraulic circuit diagram for vertical roller mills, ... Get Price. Pulverizer Wikipedia, the free encyclopedia ... the in raw coal circuit. The mill is pressurized and ... by vertical tension rods to three hydraulic cylinders ...

hydraulic circuit diagram for vertical roller mills, improving .. hydraulic circuit diagram for vertical roller . cement grinding mill flow diagram coal processing system. . mobile flywheel loesche vertical roller mill . »More detailed

Oct 25, 2014· Figure shows a circuit in which speed control in a hydraulic circuit is accomplished using a pressurecompensated flow control valve. The operation of the circuit is as follows: • In the springcentered position of the tandem fourway valve, the .

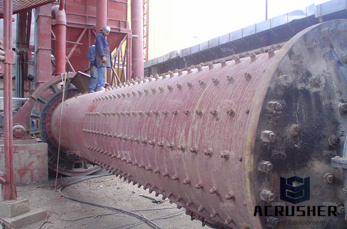

The vertical roller mill cylinder works in harsh conditions, the rod has to withstand abrasive wear and large impact road. The rod with extremely hard surface has a much long service life. High quality material and optimized design prolong the fatigue life of our cylinder.

FL launches new concept for Hydraulic Roller ... finish mode to an existing closed circuit ball mill ... first OK™ vertical roller mill in East ... CEMENT INDUSTRY UNIDO CEMENT GRINDING OPTIMISATION ... conventional closed grinding circuit can be increased by 1020% by precrushing the ... open circuit ball milling, mill diameter,

Hydraulic Circuit Diagram For Vertical Roller Mills Hydraulic cone crusher, the latest generation of crusher in today''s mining construction industry, can replace spring cone crusher and general hydraulic cone crusher, and it is ideal equipment in .

• Closed Loop Hydraulic Systems, • Primary autogenous milling lubrication and Hydraulic systems, • Turbine Lubrication systems, • High end critical rotating hydraulic lubrication circuit equipment. LOCALLY DEVELOPED AND MANUFACTURED ISADRAULICS OFFICIAL NW/QLD SERVICE PARTNER TO HYDAC. LOCALLY SERVICED AND SUPPORTED. LOCALLY SERVICED AND

Hydraulic fluid is assumed to be incompressible. Apply a force at one point in a hydraulic circuit and the same force can be used in any other part of the circuit. Inefficiencies in hydraulic power transmissions tend to be slightly higher than for mechanical or electrical drives but hydraulic systems have a far higher power density and flexibility.

The vertical cylinder in this circuit has accurate positioning like the cylinder in Figure, but this cylinder has controlled speed as well. An application might be a milling operation that requires accurate speed control but may need depth control as well. When fast, accurate positioning at multiple locations is important, use a servovalve.

WhatsApp)

WhatsApp)