Ball Mill Safety YouTube

Jul 05, 2008· Mine Safety and Health Administration Ball Mill Safety DVD573 1998 Developed cooperatively by MSHA and Lehigh Portland Cement Company. Outlines the various steps precautions and procedures ...

WhatsApp)

WhatsApp)

Jul 05, 2008· Mine Safety and Health Administration Ball Mill Safety DVD573 1998 Developed cooperatively by MSHA and Lehigh Portland Cement Company. Outlines the various steps precautions and procedures ...

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

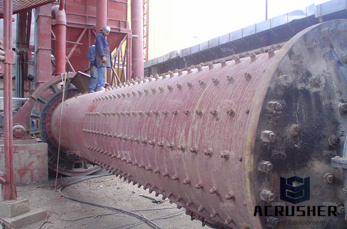

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Mar 08, 2013· re CALCULATION OF BALL MILL GRINDING EFFICIENCY. Please can anyone give me, step step by procedure on how to work out on cement ball mills to. improve it''s efficiency, optimum operation and increases output.

cement ball mill operation procedure 32971. cement ball mill operation procedure 32971. Optimization of Cement Grinding Operation in Ball Mills. Optimization of the Cement Ball Mill Operation. Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more . Get price

cement ball mill operation procedure 32971. Optimization of Cement Grinding Operation in Ball Mills. Optimization of the Cement Ball Mill Operation. Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increase the production rate as . Get Price

Horizontal ball mills have become a reliable part of grinding plants. Main characteristics of ball mills seated on shoetype bearings. Low operation and maintenance 1 – ball mill. 2 – elevator. 3 – separator VTP. 4 – separating cyclone. 5 – mill fan. 6 – separator fan. 7 – .

cement ball mill operation procedure 32971. cement ball mill operation procedure 32971. Optimization of Cement Grinding Operation in Ball Mills. Optimization of the Cement Ball Mill Operation. Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more ...

A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side. System Description Mill Rated capacity 150 t/h OPC at .

ball mill grinding media charging procedure; cement ball mill operation procedure 32971; ball mill model; ball mill used for powder making; vertical mill ball net; the time particles spend in a ball mill; primary air flow coal ball mill; specifications jaw crusher; size of inch steinert industries diamond grinder; cone crusher speaking

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement .

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Ball Mill Cyclones Weight Feeders Recycling Elevator Sep. Feed Mill Feed Sep. Return Final Product System Fan Figure 1: Closed circuit grinding system. milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement .

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

uously optimize mill operation, it is vital to obtain regular measurements of the ball load ... Ball mills are usually the largest consumers of energy within a ... suffer from the procedure that is followed by the operator. Mill power Usually, plant operators use mill power readings as an ...

Operation and Elements of a Closed Circuit Ball Mill System. Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber.

flowchart for operating cement mills what is rotary screen cement plant cement plant process mill cement production machinery turkey operating the principle of . PROCESS DIAGNOSTIC STUDIES FOR CEMENT, PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL, ball mill for cement grinding: The mill has been operating with, cement mill and the sepax .

BALL MILL STANDARD OPERATING PROCEDURE: SL PROCEDURES STATUS REMARK NO 1. Ensure that all the items mentioned in the prerequisites are available 2. Connect the power supply (3 Phase) [415 V, 50/ 60 HZ] with Earthing. (use 5 core cable to draw earthing from the input supply).

ball mill relining standard operating procedure XSM ball mill operating procedures (ball mill crasher installation procedure Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates. [24/7 Live Chat ]

Grinding media used in cement mill grinding media balls and cylpebs and high chrome cement ball mill grinding media calculation cement ball mill operation procedure 32971 grinding media cement mill segregation of grinding media of cement outside the grinding media cement mill grinding media cement mill segregation of grinding media of cement ...

Cement mill WikipediaOverviewHistoryMaterials groundTemperature controlBall MillsRoller millsA cement mill is the equipment used to grind the hard, nodular cl

mill cement mill operation procedure Videos of mill cement mill operation procedure Click to view on YouTubeHDSBM Stone CrusherYouTube · · viewsClick to view on VidoEvoCement ball mill shoe bearing operationVidoEvoSee more videos of mill cement mill operation procedure

The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative to the ball mill system and has increased its share of the market for cement mills over

Ball Mill Maintenance Manual The purpose of this manual is to assist you in the proper installation and to acquaint you a bit further with the assembly and care of this equipment. We suggest that these instructions be read carefully and reviewed by everyone whenever involved in the actual installation and operation of the mill. In [.]

WhatsApp)

WhatsApp)