What is lightweight aggregate? Quora

Lightweight aggregate(sometimes is called as low density aggregate) is a generic name of a group of aggregates for structural concrete, mortar, or plaster that weighs ...

WhatsApp)

WhatsApp)

Lightweight aggregate(sometimes is called as low density aggregate) is a generic name of a group of aggregates for structural concrete, mortar, or plaster that weighs ...

offers 322 fly ash aggregates machine products. About 1% of these are filling machines. A wide variety of fly ash aggregates machine options are available to you, such as filling machine, multifunction packaging machine, and other.

Lightweight Concrete Aggregate From Sintered Fly Ash •THE PRODUCTION of lightweight aggregate from fly ash has received the attention of investigators throughout the world (1,2). Although a number of early attempts to produce a commercial product proved"Unsucessful, recent developments give every indication that the manufacture of fly ash ...

Ceramic Lightweight Aggregate PRODUCTION FROM FLY ASH For additional information on manufacturing ceramic lightweight aggregate from coal ash, please contact a Boral Resources Technical Sales Representative or call .

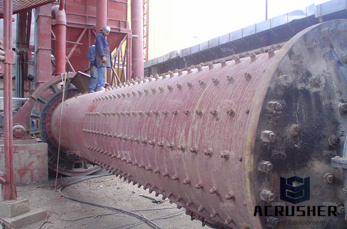

Fly ash lightweight aggregate production line Rotary . Technical parameters of fly ash lightweight aggregate production line. the scientific optimization and combination, the annual output of fly ash lightweight aggregate produced by this equipment can reach as follows: 20,000m³ 50,000 m ³ 100,000 m ³ 200,000 m ³ 300,000 m ³

InGlobal Resources, New Delhi focuses on sourcing proven plant and technology, which can produce Artificial Lightweight Aggregate (LWA) from fly ash, a waste product of coal burning power plants. The product is an excellent alternative to natural quarried aggregate, being strong, light and consistent.

EPS Cement Sandwich Roof Panel. There are two parts to a roof, its supporting structure and its outer skin, or uppermost weatherproof layer. In a minority of buildings, the .

LIGHT WEIGHT AGGREGATE : Preamble: InGlobal Resources, New Delhi focuses on sourcing advanced technology; which can produce artificial lightweight Aggregate (LWA) from fly ash, a waste product of coal burning power plants. The product is an excellent alternative to natural quarried aggregate, being strong, light and consistent.

Artificial Aggregate Production from Fly Ash Synopsis: The paper makes out a case for use of Fly Ash based lightweight aggregate, as a substitute for normal crushed stone aggregate, in making of concrete for structural and other applications. The plea is primarily based on the logic of arresting

offers 627 lightweight aggregate concrete machines products. About 67% of these are board making machinery, 8% are brick making machinery, and 4% are concrete pumps. A wide variety of lightweight aggregate concrete machines options are available to you, such as concrete, cement, and fly ash.

Salt River Materials Group manufactures and markets concrete aggregates meeting the requirements of ASTM C 33 and structural lightweight aggregates meeting the requirements of ASTM C 330 to complement fly ash and the Phoenix Cement® line of Portland and blended cements.

Fortunately, fly ash can be used as a beneficial additive in some applications – particularly in concrete products, where it is used as a lightweight aggregate (LWA).The benefits of using fly ash as a lightweight aggregate in concrete products are so great that the concrete industry has come to rely on this powergenerated byproduct.

Lightweight Aggregate (LWA) ... The facility design had the capacity to process 60,000 wet tons of sludge and 90,000 tons of fly ash into 100,000 tons of lightweight aggregate. Minergy LWA Properties and Use. Minergy LWA™ The stonelike end product.

Fly Ash Lightweight Aggregate FLY ASH AT A GLANCE Brief Introduction of LWA MeTech Fly Ash LWA Project Intro. Comparison of LWC Normal Concrete MeTech Fly Ash LWA Project Intro. Go Green Fly Ash LWC Performance Characteristics LWA Applications. MeTech Fly Ash LWA Project After agglomeration and palletizing, the green pellets are sintered ...

Lightweight Aggregate Concrete Sandwich Panel. LIGHTWALL ® (Lightweight aggregate concrete sandwich panel), is a lightweight precast concrete sandwich panel, made by calcium silicate boards as skin layers, Portland cement, expanded polystyrene (EPS) , fly ash as light weight aggregate concrete filler solid core.

The newest type of synthetic aggregate is formed primarily or entirely from reclaimed materials. The primary components are usually reclaimed plastic and highcarboncontent fly ash from coalburning power plants. Some states'' recycling programs encourage lightweight aggregates made .

Successful use of Synthetic Lightweight Aggregates made from waste flyash and plastics can help in conserving mineral aggregates and reusing waste materials. The objective of this study was to evaluate the use of Synthetic Lightweight Aggregate made from waste fly ash and plastics in Hot Mix Asphalt.

and equipment than the pelletized sintered fly ash aggregates which are commercially available. The objectives of the inventors were the following: 1) To produce highly consistent aggregate from fly ash. 2) To use such aggregate in the production of structural concrete. 3) To develop a simple and easily controllable method that can be

On the other hand, the SP aggregate is a sintered pelletized fly ash aggregate that has been a successful commercial lightweight aggregate since the 1960s and can represent the general characteristics of lightweight pelletized fly ash aggregates and their performance in concrete. Table 4 lists the properties of the three other main aggregates.

A wide variety of lightweight aggregate concrete options are available to you, such as hollow block making machine, interlock block making machine. You can also choose from concrete, cement, and fly ash. There are 800 lightweight aggregate concrete suppliers, mainly located in Asia.

•THE PRODUCTION of lightweight aggregate from fly ash has received the attention of investigators throughout the world (1,2). Although a number of early attempts to produce a commercial product proved"Unsucessful, recent developments give every indication that the manufacture of fly ash aggregate is now possible. Furthermore,

Fly ash lightweight aggregates in high performance concrete. On the other hand, the SP aggregate is a sintered pelletized fly ash aggregate that has been a successful commercial lightweight aggregate since the 1960s and can represent the general characteristics of lightweight pelletized fly ash aggregates and their performance in concrete.

Therefore, the manufacture of sintered fly ash lightweight aggregate is an appropriate step to utilize a large quantity of fly ash in concrete. However, a nonexistence of worthwhile technology to produce sintered flyash lightweight aggregates and the absence of a market has deterred Indian entrepreneurs from producing sintered flyash aggregate.

Boral offers a technology and service for the manufacture of ceramic lightweight aggregate (LWA) from coal combustion products generated by current production or recovered from landfills or ponds. The resulting aggregate can be sold and beneficially purposed in a variety of construction, agricultural, and related applications.

WhatsApp)

WhatsApp)