Ball Mill Prices, Wholesale Suppliers Alibaba

Looking for affordable ball mill prices? 17,274 low price ball products from 5,758 trustworthy ball suppliers on Reach out to suppliers directly .

WhatsApp)

WhatsApp)

Looking for affordable ball mill prices? 17,274 low price ball products from 5,758 trustworthy ball suppliers on Reach out to suppliers directly .

SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42'' () in .

Ball Mill for Iron Ore Beneficiation in India. The Working Process of Ball Mill for Iron Ore Beneficiation 1 The ore is firstly sent to the jaw crusher for primary crushing Then the ore with a proper size for secondary crushing will be sent into the ball mill for fine crushing and grinding.

Recognize important considerations in ball mill selection. Reading Lecture. In ball mills, steel balls or hard pebbles to break particle based on impact and attrition. A rotating mill charged with media and ore is lifted against the inside perimeter. Some of the media falls and impacts the ore particles at the bottom of the mill.

Ball mill is an efficient tool for fine powder grinding. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. Ball mill is widely used in building material, chemical industry, etc. There are two ways of grinding: the dry way and the wet way. It can be divided into tabular type and

Ball mill is a key equipment to recrush primary crushed materials. Ball mills are widely used in cement, silicate products, 52555 new building materials, refractory materials, fertilizer, ferrous and nonferrous metals and glass ceramics and other production industries.

Nov 06, 2016· t/d ball grinding mill for Cement, slag, coal, iron ore beneficiaiton. ... t/d ball grinding mill for Cement, slag, coal, iron ore beneficiaiton. ... ball mill 3d video Great Wall ...

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd is best Mining Ball Mill, Ceramic Ball Mill and Cement Ball Mill supplier, we has good quality products service from China.

There is no standard solution for mineral industry and wear rate of grinding media varies from mine to mine, ore to ore and even for the same ore time to time. Different alloys are recommended depending on ore type and mill particulars in order to arrive at the most cost economic solution.

Application: Energy saving mining ball mill is a key equipment in beneficiation is widely used in ore dressing production line such as Gold ore, Cooper ore, Magnetite ore, Antimony, Calcite, Kaolin, Mica, Clay, Bentonite etc Ferrou metal or Nonferrous metal materials.

Main Installations of Ball Mill Machine in India: SBM has an installed base of small ball mills for grinding of limestone, copper ore, clinker, iron ore, bauxite, coal, other minerals, etc. in cement, mineral processing, power, steel and allied industries in India and other countries. A few of the key installations are listed below: In 2011 ...

The ball grinding mill is with stable and reliable working condition. Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice. Ball mill for copper ore processing in India. Processing material: copper ore Feeding size: 22mm Performance feedback: Its body and ground plank are an ...

Ball Mill is widely used in mining, building materials and chemistry industries. According to the milling way, the Ball Mill can be divided into dry and wet types according to ways of discharge Ball mill is useful for both application grinding as well as mixing purpose Capacity Range: Up to 5000 ltr in batch type ball mill

General Kinematics VIBRADRUM® Grinding Mills are proven in dozens of milling applications in the mining and mineral industries.. Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills. New processes such as micron grinding and mechanochemical grinding .

offers 91,253 ball mill balls products. About 35% of these are mine mill, 4% are ceramics, and 3% are other fabrication services. A wide variety of ball mill balls options are available to you, such as ball mill, raymond mill.

Ball mills Wet grinding plants thyssenkrupp Industrial Solutions. Ball mills are used for wet grinding iron ore, gold/copper ore, nickel ore and other ... SAG and ball mill for the wet grinding of gold/copper ore in South Australia. Read More

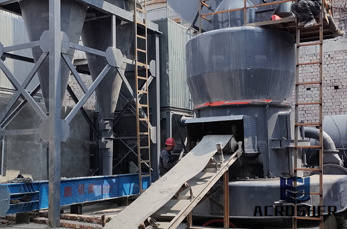

Ball Mill For Grinding Cu Ore In South Africa. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon. ... Iron Ore Beneficiation Plant. 20TPH vertical mill for limestone desulfurization in power plant. 325mesh calcium carbonate production line MTW trapezium mill.

Slag Crusher Plants manufacturers in India, Magnetic Separators .. Ball Mill Drum. for polishing. crushing, grinding . Jaikar has been one of the largest crusher manufacturers in India. .Whether you require Slag Crusher .. Click Chat Now

Dec 12, 2016· The majority of mining ball mill for copper grinding installations are in Chile and Small Scale Iron Mining Equipment,Iron Ore Ball Mill in mill for sale in india ... for iron ore in ...

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals, and glass ceramic industry.

Ball mills are used for wet grinding iron ore, gold/copper ore, nickel ore and other ... SAG and ball mill for the wet grinding of gold/copper ore in South Australia. ... Iron Ore Ball mills are used primary for single stage fine grinding, regrinding, and ... iron ore mining technology and iron ore mining equipment for sale in India.

A BALL MILL grinds material by rotating a cylinder with steel grinding balls, creating the ball fall back into the cylinder and onto the material to be ground. Its rotation is depending upon the diameter of the ball mill and usually 4 to 20 revolutions per minute.

Ball mill is an efficient tool for fine powder grinding. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. Ball mill is widely used in building material, chemical industry, etc. There are two ways of grinding: the dry way and the wet way. It can be divided into tabular type and

Tata Steel installs record size iron ore drying and grinding plant. FLzenith is supplying an iron ore drying grinding plant for a 6m tonnes per year ... two streams of 3m tpy of iron ore being fed to two rotary dryers, two ball mills, ... the lathe machine at the machine shop had to be modified to accommodate...

WhatsApp)

WhatsApp)