: 1 TPH Impact mill for small scale ... YouTube

Jan 15, 2013· We will upload videos of the impact mill when its finished. It will be fed by an 8x8 jaw crusher and can take material 1/2"1" in size and reduce it .

WhatsApp)

WhatsApp)

Jan 15, 2013· We will upload videos of the impact mill when its finished. It will be fed by an 8x8 jaw crusher and can take material 1/2"1" in size and reduce it .

Feb 11, 2017· The jaw crusher and impact mill combination will be powered by an Iseki TX2140 15hp tractor with 1000rpm PTO onto a slasher gearbox with :1 increase .

Pulp Shortages and Price Increases 2017''. The aim of this paper is to explain the historical factors and current political policies affecting the Global Paper Market, shortages and price increases. The packaging industry continues to grow in strength as retailers accept the need for packaging supplies, that both protect goods and look attractive.

Using a 4% cap rate, the impact increases to 536 per mill, or 5,400 for every 10 mills. It should be noted that homeowners'' association fees paid by an apartment community have a similar impact on value, which can be calculated by dividing the annual per unit HOA fee by the assumed cap rate.

CSE Uniserve''s Modern SER Drive offers robust mill control, lower energy use and higher power ratings than other mill drive technologies. It is the only mill controller with the ability to offer 100 per cent motor torque at hypersynchronous speeds for single or dual motor mills up to 22MW, an exclusive benefit no other technology can match.

The class of gravitational impact mills that incorporate steel balls in the chamber are appropriately referred to as "ball mill". Dynamic impact mills. Dynamic impact would occur when material is dropped into a chamber where it receives a pulverizing blow from a [Hammermill|hammer]], rotor or pin.

Whether it''s a simple process review or a service contract, CMS is the industry leader who is at your service. We are the experts at impact mill and other grinding equipment installation, safety procedure training, and more. Remember, confidential consultations and assistance is available nationwide.

Images of crusher machine images of crusher machine grinding mill china crusher the free encyclopedia a crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust crushers may be used to reduce the size or change. Read More NEWS; Cone crusher machine picture

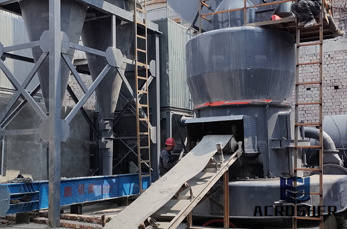

The impact mill is one of the latest inventions in the milling industry. Its design is meant to reduce on power consumption and maximize on efficiency. Its operation does not incorporate screening mechanisms as compared to the old models.

Definition of FHT Flour Heat Treatment is a process designed to modify the properties of flour, germ, and bran. FHT can be divided into ... • increases the hot viscosity of these flours ... Impact mill Hammer mill Plansifter Magnet Magnet Impact mill Pneumatic conveyor/ aspiration filter (B4Cup) 2000

Current technology does not permit bleach effluent to be recycled. If it is sent through the recovery process, salts build up leading to corrosion and scaling. Hence, the bleach plant accounts for fully half of the effluent that comes from the Kraft mill. Total water use in a Kraft mill .

6 days ago· Why dividend increases matter. ... We don''t just invest for current income, but we are investing for a larger, future income too! ... is proof that the dividend increases impact my portfolio in a ...

Jan 18, 2017· The rotor impact mill of type RPMV 1513 is the centerpiece of the shredding stage: It crushes the remaining material and separates it. In doing so, it works selectively, finely crushing brittle materials such as mineral substances, glass and castings and separating composites. Elastic materials such as rubber, on the other hand, remain intact.

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill).

Jul 11, 2018· New Labor Department Figures Demonstrate How New Tariffs Have Increased the Costs of Key ... percent for copper and brass mill shapes and percent for steel mill products between June 2017 and June 2018. ... "The broader impact of the new tariffs and the trade fights that are now emerging is a significant and costly loss in ...

why coal mill use pfister; why you need mobile stone crusher; why is sieving important in mineral processing; why we use diaphragm plate in cement mill; why crushed bauxite; why current increases in a impact mill; why do wee need to quarry calcium carbonate; why does the secondary jaw is smaller in stone crusher; why do we need silica sand

Sep 25, 2019· WestRock recently announced a mill reconfiguration will add 40 million in EBITDA annually. Some investors may lobby for these funds to be considered when WestRock increases its dividend in October.

minimumimpact mill should begin by ... Furthermore, current environmental ... Will demand for wood increase due to lower process yields? Will energy

Several mills in Scandinavia have placed TEF (totally effluentfree) or MIM (minimum impact mill) products on the market, seeking premiums, but have not achieved any significant success. But effluent closure or minimum impact could become a fairly significant marketing tool for the pulp and paper industry in the twentyfirst century.

The commonly used grinding equipment is a roller mill. The auxiliary grinding equipment includes an impact mill and a loose powder machine. Flour Milling Theory Brief Introduction. Grinding and sieving milling method mainly uses the difference in the strength of wheat endosperm and cortex to separate the cortex from the endosperm.

Aug 14, 2017· Since 2010, both the average and median mill rates in the poorest communities have grown twice as fast as in the betteroff communities. Revaluations of property also impact mill rates.

Both lactose granules and extruded lentils were used to determine the effect of size reduction parameters in the pharmaceutical milling process. The 10kg of extruded lentils (extrudate) used in the study were pulled from line production at the completion of hotmelt extrusion. Within

Pharmaceutics Test 2 PwrPt1 Micromeritics. STUDY. PLAY. ... Oral Dosage Forms. Drug must dissolve to be absorbed Solubility increases with increased surface area Decreasing particle size, increasing porosity, and increased irregularity (shape) increases surface area ... Impact Mill, Conical Mill Drug Substance Jet Mill, Wet Mill.

End Peripheral discharge and center peripheral discharge rod mills are described in detail on pages 28 and 29. Feed and discharge heads of Rod Mills are conical in shape providing important advantages over a mill with straight heads. 1. They provide the essential feed pocket and also a space for the pulp to squeeze from the rod mass.

WhatsApp)

WhatsApp)