Mitsubishi Materials Web Catalog|Solid End Mills

Ball Nose Type Medium; 2flute ball nose end mills with medium cutting edge length for general use. Excellent performance for a wide range of workpiece materials .

WhatsApp)

WhatsApp)

Ball Nose Type Medium; 2flute ball nose end mills with medium cutting edge length for general use. Excellent performance for a wide range of workpiece materials .

Ball end mills have a rounded nose and create a roundbottomed groove in milling tasks. Also known as ballnose end mills, they are rotated against a workpiece to make roundbottomed slots and pockets or mill complex shapes without sharp corners. ... Milling Dia. 1/32" (15) 1/16" (8) Number of Flutes . 2Flute. Tools have more chip capacity and ...

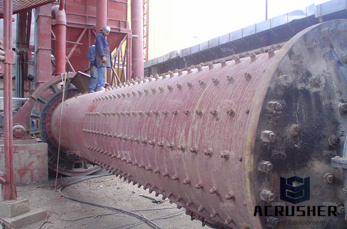

Jul 20, 2012· BALL MILL: Size Material Of Construction Mild Steel. Having Total Volume Capacity In Liters . Main Shell Will Be Fabricated In Mm Thick Plate And Side Plate Will Be Mm Thick And ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world. Since this minireview mainly focuses on the conditions applied for the preparation and ...

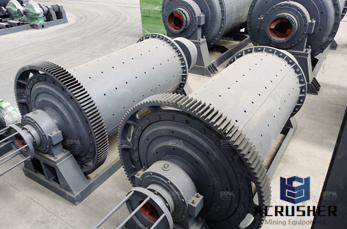

Unused Patterson Ball Mill; 5'' Diameter X 6'' Long. Unused Patterson Ball Mill; 5'' Diameter X 6'' Long, Type D, nonjacketed, with AR400 steel liners. Includes 30 HP, 3 phase, 60 Hz, 230460 V, 1725 RPM motor. Mill drive is integrally coupled to horizontal parallel shafted helical gear reducer.

Aug 10, 2020· Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder. Ceramic material, crystalline compounds, and even some metals can be ground up using a ball mill.

Also known as ballnose end mills, they are rotated against a workpiece to make roundbottomed slots and pockets or mill complex shapes without sharp corners. Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent damage to the end mill or workpiece. End mills are used on CNC or manual milling machines.

Apr 22, 2016· Mechanochemistry using ball mills is a promising technique with applications in organic and inorganic chemistry as well as material sciences [1–4].During ball milling, up to 80 % of the energy that is generated in the mill is dissipated as heat [].This is why measurement and control of the temperature in the ball mills is important, for example, if heatsensitive products are formed that ...

ball mill chinayoutube; ... ball mill 4f dia 10f. Part Description Dia. ... China ball mill,Ball mill price,Ball mill for sale,Ball mill grinder,Ball ... Get Price; admin 161/390 . Glass rotameter DK8004F 644 024 00 640 991 24 NI15M30AP6X/S100 ... (Dia: 620MM Height:19MM) valve ... Get Price; cement balls segregation machine .

A plant technician has measured the pulp densities of the process streams using a Marcy density gauge and reported the following: Ï f = gm/ml, Ï o = gm/ml and Ï u = gm/ml. Determine the volumetric flow rates to each stream.

Therefore, ball abrasion rate in the mill determined by Equation 10. A𝑟= At F = 131328 = g/ton (10) In above equations: 𝑣m: 3total mill volume (m ), 𝑁: number of balls which exist in mill, 𝐴𝑏: each ball abrasion (g), 𝐴t: total ball abrasion in the mill (g), 𝑣b: each ball volume (m3), 𝑓b:

A Hp 3 Phase 50 Cycle 440=/V Motor Coupled To A Worm Reduction Gear Box Of Center, Is Mounted On A Separate Base Frame And Drives The Mill At Rpm. A Girth Gear With Matching Pinion Is Fitted On Mill Of Size 4'' Dia. And Above. Note: Working Capacity Will Be 25 To 35% Of Total Capacity After Loading Grinding Media.

conical ball mill crusher hardinge conical mill for mining ball mill 4f dia 10f description : used ball mills for sale from nelson machinerymill, ball, 04x02, 1, 4''6" x 24" hardinge conical Get Price + Ball Mills Klinger Machinery Company, Inc. Ball mills at Klinger Machinery Klinger Machinery Company, Inc PO Box 306, Elizabethville Pa 17023 .

Destiny end mills also form a manageable "6" and "9" shaped chip by traveling down through the gullet to the core diameter of the end mill. However, we have developed a rake face geometry that enables the material to curl in the outer rake face as you can see by the red arrow above. By doing this we create much less friction (and HEAT) in the tool which translates to longer tool life.

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Calculations use the desired tool diameter, number of teeth, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material.

Inventory ID: 6CHM02. UNUSED FL 22'' x 41''6" Dual Pinion Regrind Ball Mill with 2 ABB 5,500 kW (7,375 HP) Drives for Total Power of 11,000 kW (14,750 HP)

The productivity of ball mills depends on the drum diameter and the relation of ∫ drum diameter and length. The optimum ratio between length L and diameter D, L:D, is usually accepted in the range – The mill productivity also depends on many other factors, including the physicalchemical properties of the feed material, the filling ...

Ball Mill Product Size (Cyclone O/F) P80 106 micron The initial selection at this stage was for a single 34'' dia. x 17''6" flange to flange long, twin pinion, MW SAG Mill and a single 24'' dia. x 36'' flange to flange long, twin pinion, 12 MW secondary ball mill.

Gates,, Giblett, A, Dunne, R. (2012) Prediction of plant ball mill media wear rates from laboratory ball mill test data, Comminution ''12, Minerals Engineering. Wear of grinding media in the ...

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Jul 28, 2020· Ball mill installation is a must step before it is put into production, which will affect the subsequent use of the ball mill, and even affect the production volume, crushing rate, service life, etc., so the importance of ball mill installation is selfevident.. In addition, the choice of grinding medium is also crucial. In the grinding process, different grinding medium can be used for ...

The ball impact energy on grain is proportional to the ball diameter to the third power: 3 E K 1 d b. (3) The coefficient of proportionality K 1 directly depends on the mill diameter, ball mill loading, milling rate and the type of grinding (wet/dry). None of the characteristics of the material being ground have any influence on K 1.

Mill Diameter Mill Length Installed Power Mill Volume Power Intensity (m) (m) (kW) m3 (kW/m3) Autogenous Mill 10 6400 353 18 Ball Mill 5 2600 126 21 Regrind Ball Mill 740 39 19 Tower Mill 520 12 42 IsaMill 3 1120 3 280 3 3) 23/m) Ball Mill Tower Mill IsaMill (m Power Intensity Media Size No. Balls / m Surface Area ...

WhatsApp)

WhatsApp)