Cement packing plant YouTube

Jan 25, 2011· A tour through the process of packing cement in 50 kg bags, at the Ramliya II cement plant i Egypt. The paking machines is supplied by Ventomatic. The packing plant consist of three packing ...

WhatsApp)

WhatsApp)

Jan 25, 2011· A tour through the process of packing cement in 50 kg bags, at the Ramliya II cement plant i Egypt. The paking machines is supplied by Ventomatic. The packing plant consist of three packing ...

Jan 09, 2012· CEMENT LUMPS IN BAGS . Recently, we have received a complaint regarding soft lumps, reverses back to powder form when fingerpressed, and because of that the affected cement were not used due to fears that quality has been severely affected. Was the quality personnel right in not using the affected cement?

The Cement is taken by a Bucket Elevator into a bin via a spring loaded vibratory Conveyor. From here it goes to a packer having 12 outlets. It is packed into sacs of 50 kgs each.

Cement Plant Location Information for Canada. Cement plant locations and information on Canada can be found below. For full access to the database, purchase The Global Cement Report.

Cement plant laboratories check each step in the manufacture of portland cement by frequent chemical and physical tests. The labs also analyze and test the finished product to ensure that it complies with all industry specifications. The most common way to manufacture portland cement is through a dry method.

76 Ready Mix Concrete Plant Supervisor jobs available on Apply to Plant Supervisor, Plant Manager, Production Supervisor and more!

primarily for decorative purposes. Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. The sixdigit Source Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is ...

offers 13,149 cement bag plant products. About 3% of these are dry mortar machines, 3% are other packaging machines, and 1% are concrete batching plant. A wide variety of cement bag plant options are available to you, such as free samples, paid samples.

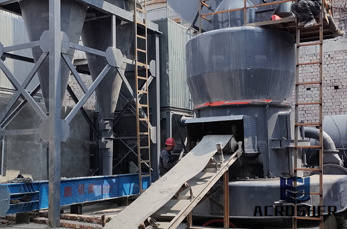

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Stationary Concrete Plant. The stationary concrete plant is designed for produce highquality concrete. It has the advantages of large output, high efficiency, high stability and high specification. Stationary Concrete Batching Plant adopts reliable and flexible components, making it easy to maintenance and owning a low failure rate.

Download 27,730 Cement Plant Stock Photos for FREE or amazingly low rates! New users enjoy 60% OFF. 118,471,847 stock photos online. Page 4

Oct 01, 2019· Vox Pro Ltd...Solutions Provider Solutions Provider for Video and Broadcast Productions Trinidad and Tobago For More information or Quotes Call: +1(868) https://

The total operation includes 11 integrated plants, one white cement plant, one clinkerisation plants, 15 grinding units, two rail and three coastal terminals, and 101 ready mix concrete (RMC) plants. Additionally, the company is the largest clinker exporter in India. | PowerPoint PPT presentation | free to view

329 Cement Plant Operator jobs available on Apply to Plant Operator and more! ... Operating a bulk plant cement trailer while on job site. ... Supervise and assist various plant maintenance functions. Plant operations includes batching, order taking, dispatch and facilities management. ...

PLANT OPERATOR DAILY SAFETY CHECKLIST: Operators are required to check the following items before commencing work. These records form the basis of a plant maintenance procedure and will be subject to random inspection. Keep record with machine at all times. OK, no obvious defect . BEFORE COMMENCING OPERATIONS CHECK M T W T F S S

Cement control 14. Packing anddistribution15. Dust collectors 16. Maintenance17. Process 18. Materialsanalysis19. Plant capacitysummary20. ... Cement plant operations handbook for dry process plants : [the concise guide to cement manufacture] Subject: Dorking, Surrey, Tradeship Publ., 2014

Fully revised and updated with improved content, the new Sixth Edition of the Cement Plant Operations Handbook is now available. Covering some 300 pages, the cement industry''s favourite technical reference book offers indepth information on the various aspects of cement .

Model available for download in #

Industrial cleaning solutions for CEMENT INDUSTRY ... Proper housekeeping aspects essentially include control of dust levels and keeping the surrounding areas clean and dust free. A cement plant is usually a township located in far off places with self sustained facilities, including hospitals, residential facilities, eateries and schools ...

Sep 14, 2014· JK Lakshmi Cement Manufacturing Process JK Lakshmi Cement. ... Asphalt batching plant 3D video by Atlas Technologies Pvt. Ltd., ... Cement packing plant Duration: 3:09. Ramliya2 162,804 views.

Cempacksa, Cement Packers South Africa, Cement Packer Machinery, cement roto packer, outsourced production management, cement packing plant, palletiser, automatic bag placers, plastic stretchood machine, conveyors

Indeed may be compensated by these employers, helping keep Indeed free for jobseekers. Indeed ranks Job Ads based on a combination of employer bids and relevance, such as your search terms and other activity on Indeed. ... concrete dispatch, concrete operations and others as ... Be the first to see new Concrete Plant Operator jobs. My email:

offers 4,298 cement packaging machine products. About 15% of these are other packaging machines, 8% are dry mortar machines, and 8% are packaging line. A wide variety of cement packaging machine options are available to you, such as free samples.

Aug 30, 2012· Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

WhatsApp)

WhatsApp)